VacTrac

Overview

The VacTrac III provides a robust and cost effective way to confirm a minimum standard of vacuum or pressure on a metal closure. The VacTrac uses a inductive, non-contact inspection sensor that has proven to be exceptionally accurate and reliable, inspecting tens of millions of containers without compromise in environments where the closures may have moisture on the surface.

The VacTrac III offers a modern computing platform which delivers an easy to use system interface coupled with powerful online support when you need help. Also, the VacTrac can be purchased with an optional analytics package that provides exceptional insight into the machine’s inspection performance and the production line’s operation.

Features

Real-Time Remote Support

Robust IT Security

No Requirement for Container Spacing

High Reliability Non-Contact Inspection

Vacuum Verification for Cans

Pressure Verification For Pull Tab Containers

Tamper Evident Band Inspection

Typical Applications

Seamed Metal Containers

Ring-Pull Containers

Plastic and Glass Containers with Metal Lids

What Makes Peco Inspx X-ray Systems Different?

High Speed Operations

Service

Software

Made in America

Tech Specs

Technical Information

Architecture

Conveyor

Aperture Size

Environment

Line Speed

Input Voltage

Air Supply

Ambient Temperature

Container Ejection

Dimensions (LxDxH)

Safety Rating

Computer

Connectivity

Supported SCADA Systems

Deflection Accuracy

Operator Interface

Construction

Technical Information

Options

Cocked/Missing Cap Detection

The cocked/missing cap sensor for plastic closures is an inexpensive way to ensure that containers are properly capped

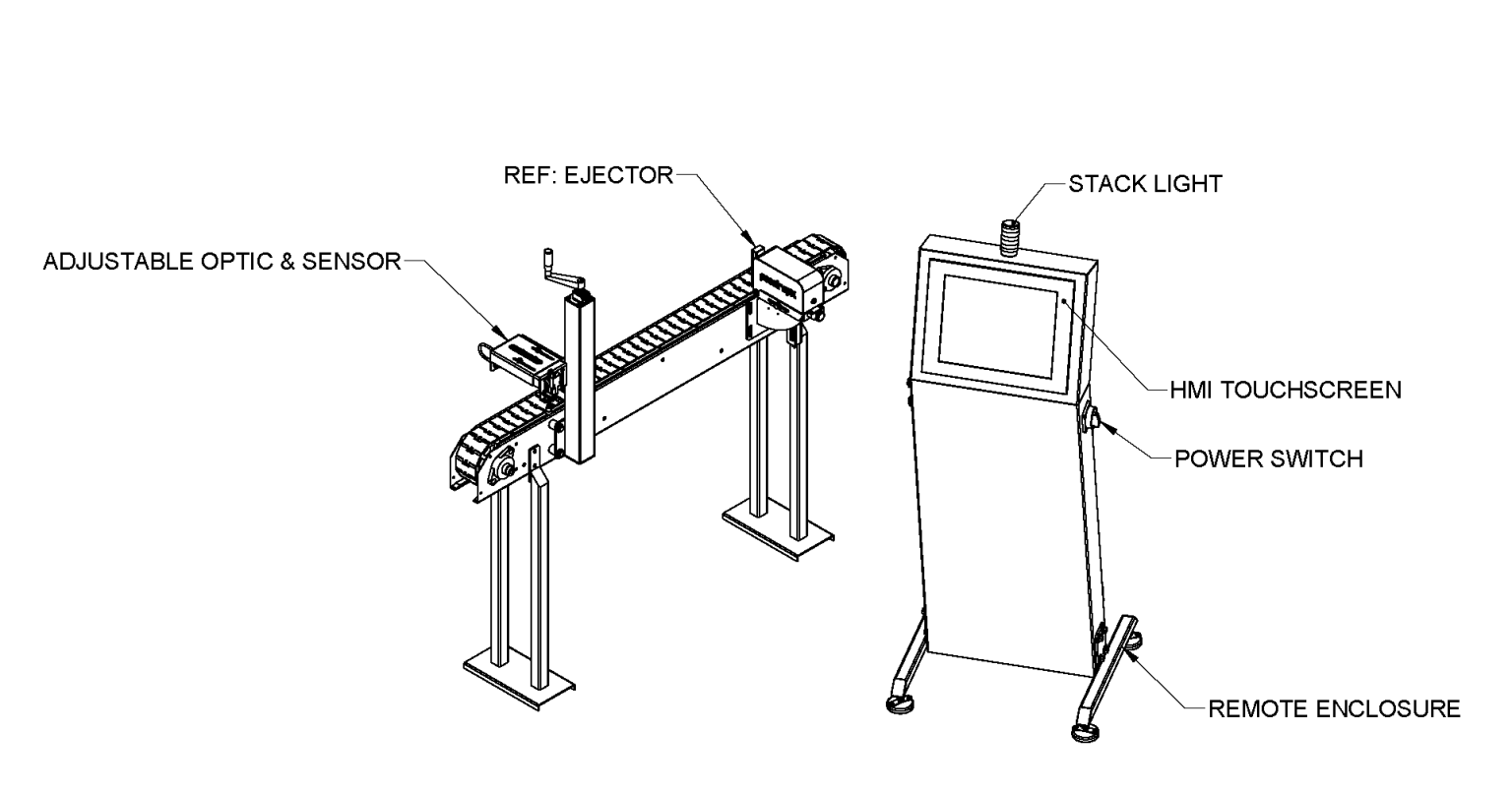

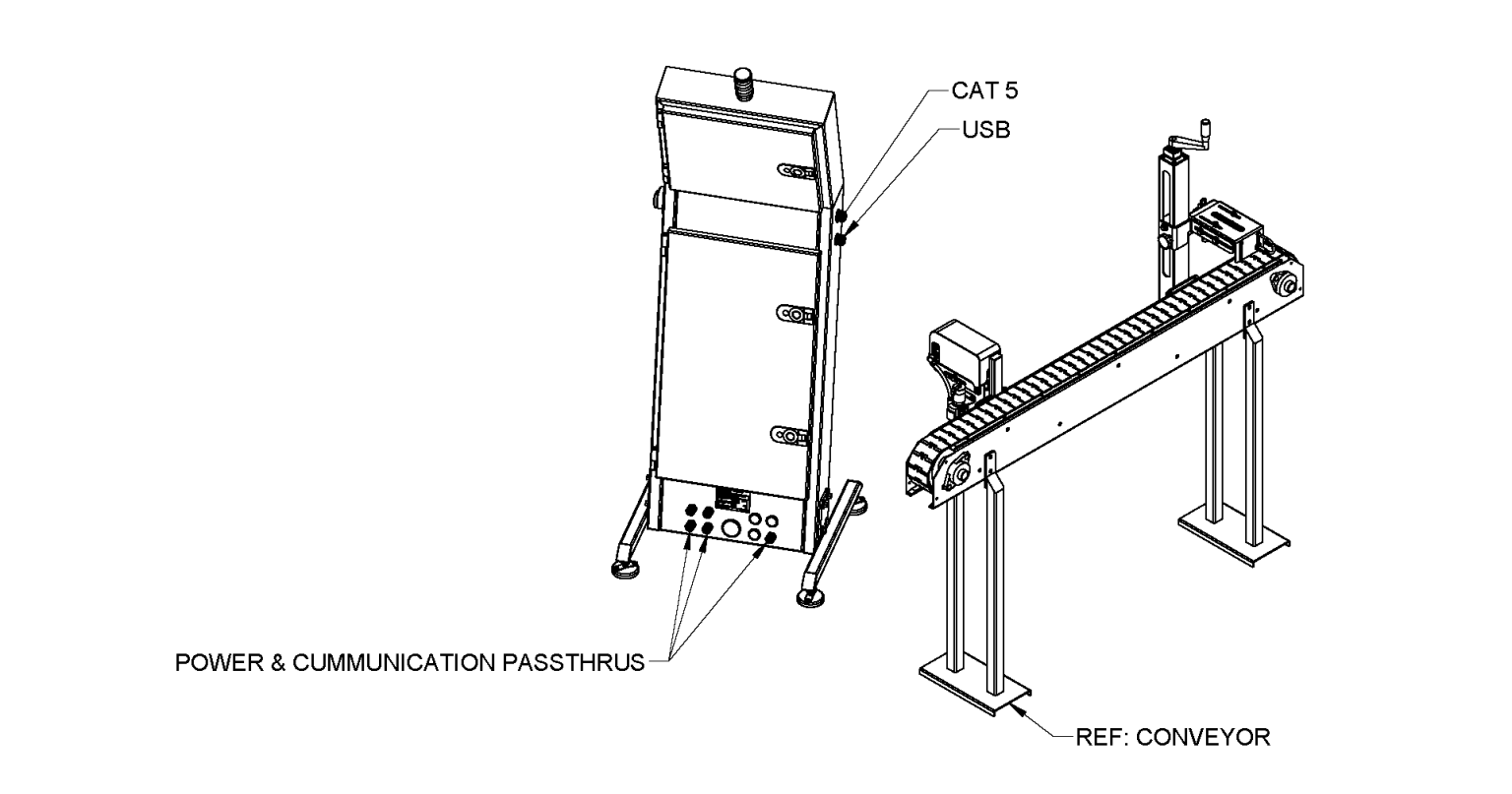

Remote Operator Console

The remote operator console provides complete system monitoring and control up to 6 meters from the system inspection assembly

Sanitary Design

Can be equipped with an IP69K enclosure for high pressure wash down environments

Missing Foil Detection

The missing foil sensor verifies the presence of foil seals under caps

Reject Management Package

Reject Management Package include secure options:

- Lockable reject bin to ensure authorized access to rejected packages

- Sensors to ensure positive confirmation on expected rejects

- Sensors to alert on “bin full” condition

- Air pressure sensor to alert for any out-of-range air supply problems

- Optional software-controlled lock for user configurable access

Full Range of Ejection Options

Peco InspX designs and manufactures a wide range of high performance ejectors and diverters to include single solonoid, multiple solonoid, swing arm, lift gate, drop gate, air blast, flexible rail, guided path, and heavy duty options