Allegro

Overview

No other top down X-ray system on the market offers such a robust set of standard features coupled with high performance options typically only available on machines costing thousands more.

The Allegro is also inexpensive and straightforward to maintain. Superior Peco InspX service ensures that you’ll have access to immediate support 24×7 and convenient local service when you need it. And because the Allegro is designed for reliable operation, you’ll be pleased with its low cost of ownership.

Features

Modular Design

Conveyor Drive

Real-Time Remote Support

Robust IT Security

No Requirement for Container Spacing

High Performance Generator

Typical Applications

Low Profile Packages and Trays

Bulk or Loose Ingredients

Low Profile Packages and Trays

Multi-Packs and Smaller Cases

What Makes Peco Inspx X-ray Systems Different?

High Speed Operations

Service

Software

Made in America

Tech Specs

Technical Information

Architecture

Conveyor

X-ray Tube Configuration

Aperture Size

Environment

Line Speed

Input Voltage

Air Supply

Ambient Temperature

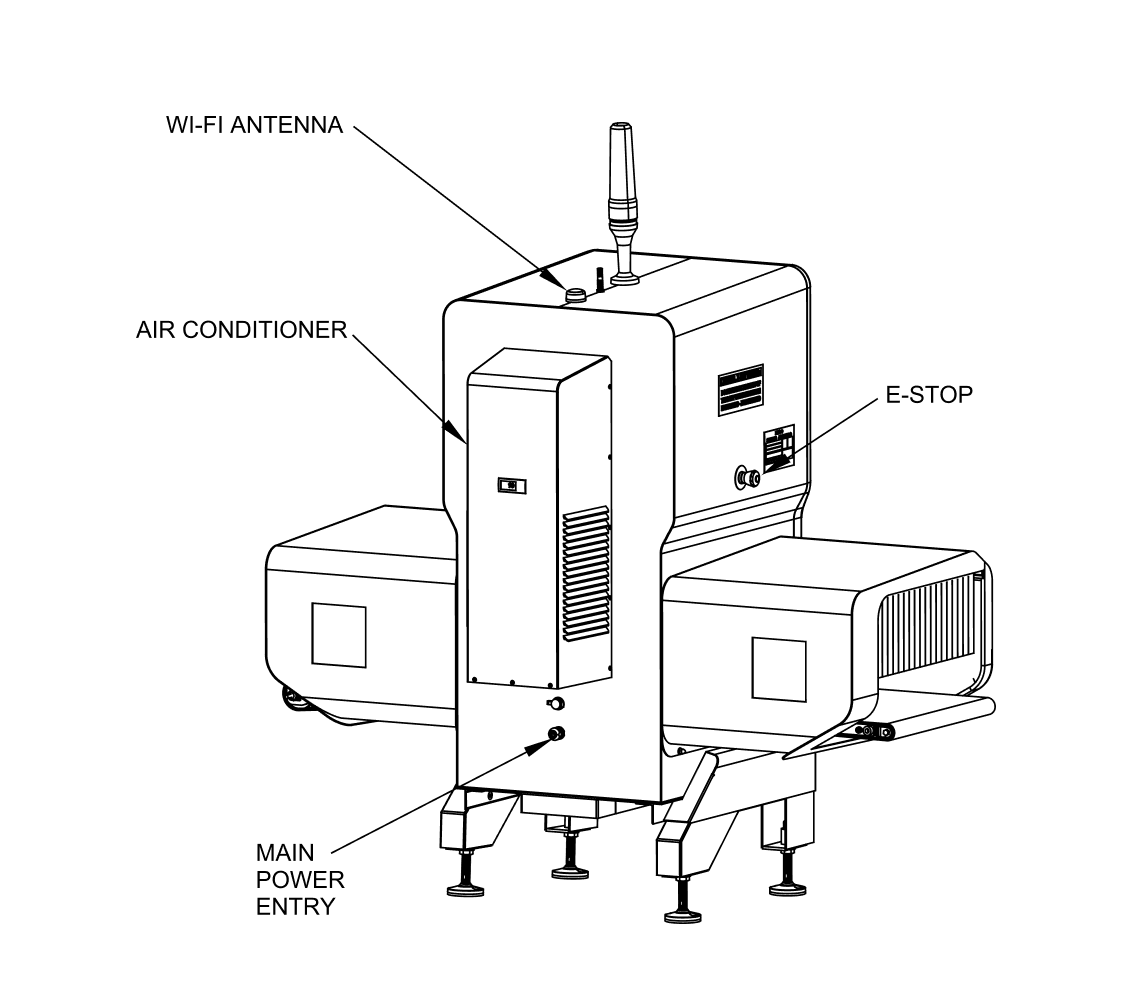

Air Conditioning

Diode Size

Container Ejection

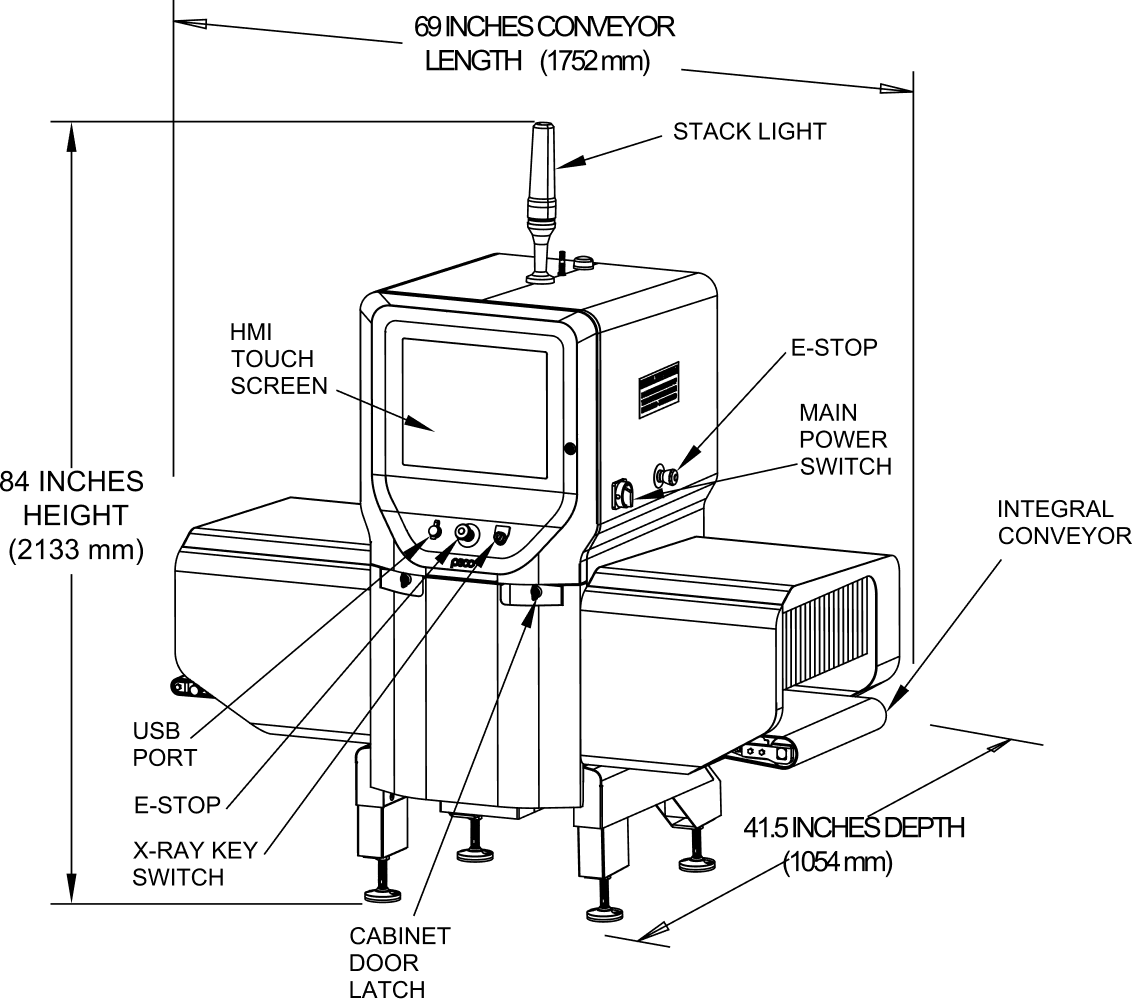

Dimensions (LxDxH)

Safety Rating

Computer

Connectivity

Supported SCADA Systems

Supported Cloud Platforms

Operator Interface

Construction

Technical Information

Options

Industrial IoT Capabilities

Peco InspX offers industry leading plant connectivity and remote control including:

- SCADA integration via OPC-UA protocol into Ignition, Wonderware, FactoryTalk, Kepware and all other popular integrated software platforms

- Native support for Azure, AWS, and Google Cloud via MQTT

- Real time system and performance monitoring of each machine

- Insight into operational performance bottlenecks

- Automatic archiving and classification of reject images

- Optional archiving of all inspection images

Reject Management Package

Reject Management Package include secure options:

- Lockable reject bin to ensure authorized access to rejected packages

- Sensors to ensure positive confirmation on expected rejects

- Sensors to alert on “bin full” condition

- Air pressure sensor to alert for any out-of-range air supply problems

- Optional software-controlled lock for user configurable access

Track and Trace Capabilities

In collaboration with industry-leading industrial package printers, Peco InspX offers an end-to-end package tracing system that prints on the inspected container the status (good or bad) of every package to ensure packages are auditable to their inspection results and X-ray image

Full Range of Ejection Options

Peco InspX designs and manufactures a wide range of high performance ejectors and diverters to include single solonoid, multiple solonoid, swing arm, lift gate, drop gate, air blast, flexible rail, guided path, and heavy duty options

RFID Access Control

Support automatic system authentication using customer ID badges. Supports a wide range of standard access protocol frequencies

Remote Operator Console

The remote operator console provides complete system monitoring and control up to 6 meters from the system inspection assembly

Sanitary Design

Can be equipped with an IP69K enclosure for high pressure wash down environments