Inspecting large-format #10 (aka, 603) cans has always been a technical challenge. These thick-walled steel containers hold several pounds of dense product, making it difficult for traditional inspection systems to detect foreign material or measure fill level reliably.

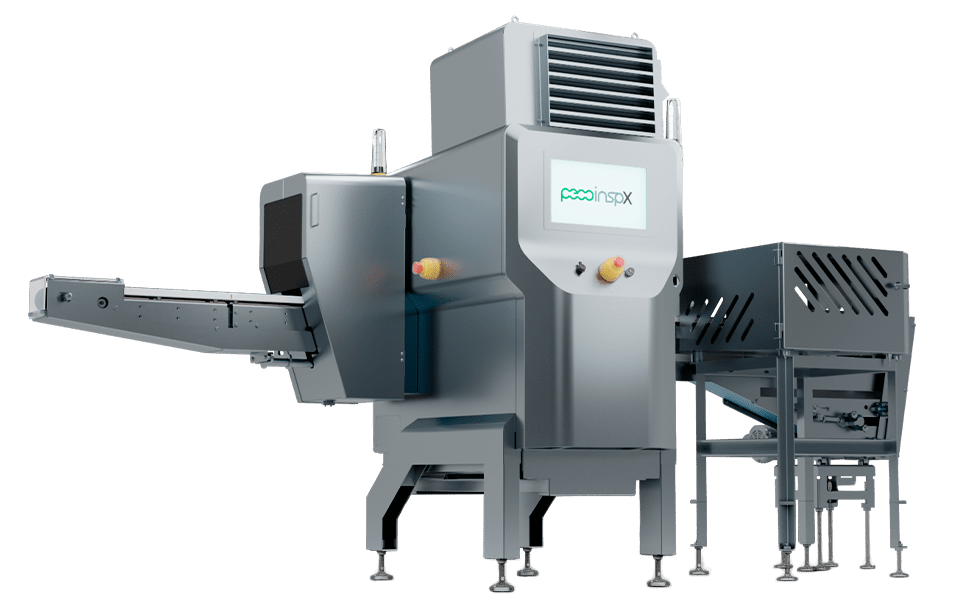

Enter the Peco InspX Crescendo, a next-generation X-ray system purpose-built for the task. The Crescendo uses a dual-beam X-ray design, including a second beam mounted on an adjustable elevator, allowing unmatched coverage of the full can volume with maximum inspection accuracy.

Why Inspecting #10 Cans Is So Difficult

- High density & volume: #10 cans are packed with thick, heavy product—meaning more material to penetrate and more opportunities for contaminants to hide.

- Variable fill content: A mix of solids and liquids complicates detection, and single beam systems struggle to provide accurate inspection for the entirety of the can, especially toward the top.

- Risk of bottom contamination: Foreign materials like stones, bone, metal, and glass often settle at the bottom—precisely where detection is hardest due to overlapping density.

How Crescendo’s Dual-Beam System Solves the Problem

Independent Focus Zones: The Crescendo’s lower X-ray beam is dedicated entirely to the bottom and sidewall of the can—areas where foreign materials are most likely to settle and where detection is most difficult. By focusing this beam purely on contaminant detection in the lower zone, Crescendo maximizes sensitivity exactly where it’s needed most.

Adjustable Second X-ray Beam: The second X-ray beam, mounted on an elevator system, is fully adjustable to target the top portion of the can. This flexibility allows it to:

- Measure fill height with high precision, even through foam, liquid, or variable solids.

- Detect foreign materials or contaminants that may be suspended in upper layers of the product.

By decoupling these two tasks—foreign material detection at the bottom and fill verification at the top—Crescendo delivers full-can inspection without compromise.

Precision Inspection at Production Speed: Even with its dual-beam setup, Crescendo is built for real-world production environments. It seamlessly integrates into existing lines on existing conveyors and inspects large, heavy cans at the highest speeds in the industry, ensuring safety and compliance without sacrificing throughput or efficiency.

Protect Your Brand, Product, and Line Performance

With rising safety expectations and increased retailer scrutiny, inspecting #10 cans for foreign material and fill accuracy is no longer optional—it’s essential. The Peco InspX Crescendo gives food manufacturers a powerful tool specifically designed to tackle the challenges of large-can inspection.

By combining a powerful lower beam for dense product zones with an adjustable top beam for fill-level accuracy and contaminant detection, Crescendo ensures no part of the can goes uninspected—protecting your brand, your bottom line, and your customer’s safety.