In the world of high-speed canning, ensuring consistent product weight is critical. But when it comes to multi-fill operations—where containers receive multiple product additions (such as solids plus liquid fills)—maintaining weight accuracy becomes even more complex. Traditional checkweighers often struggle in these environments, leading to higher false reject rates, quality issues, and reduced line efficiency.

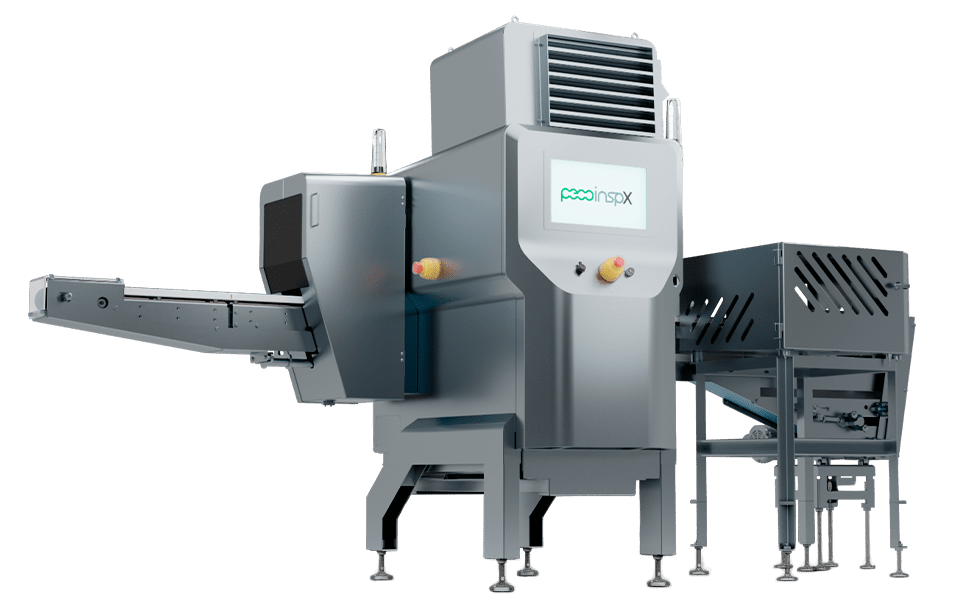

Fortunately, Peco InspX X-ray inspection systems offer a smarter, faster, and more reliable solution.

Why Multi-Fill Canning Creates Checkweighing Challenges

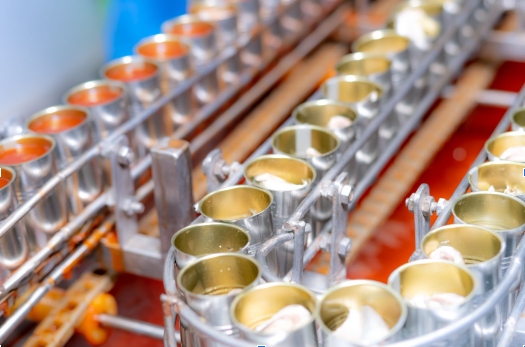

In a simple, single-fill process (like a beverage line), checkweighing is relatively straightforward: measure container weight before and after filling, and confirm it matches the target. But in multi-fill canning—common in industries like seafood, pet food, prepared meals, and specialty vegetables—things get trickier.

Here’s why:

- Multiple Components: Solid ingredients (like tuna, beans, or diced vegetables) are often added first, followed by brines, sauces, or gravies. The proportion of solids to liquids can vary from can to can.

- Inconsistent Distribution: Solids may not settle evenly within the container, affecting weight distribution and making it difficult for a standard checkweigher to get an accurate read.

- Moisture Absorption: Some solids absorb liquids during processing, changing the weight profile over time.

- Surface Variability: Product splash, foam, or uneven fills can confuse traditional weight-based systems.

The result? More false rejects, inconsistent product quality, and unnecessary downtime—all of which hurt yield, line speed, and profitability.

How Peco InspX X-ray Systems Solve the Problem

Peco InspX X-ray systems approach inspection differently—analyzing the X-ray density profile of each container instead of relying solely on surface weight measurements. This method offers critical advantages for multi-fill operations:

1. Accurate Fill Verification Regardless of Distribution

X-ray inspection measures the actual mass inside the container, detecting even small discrepancies regardless of how the solids and liquids are layered. Unevenly distributed solids? No problem—X-ray sees the total content, not just the container’s center of gravity.

2. Real-Time Analysis Without Line Slowdown

Peco InspX systems are built for high-speed lines, operating comfortably at 2,000+ containers per minute. Multi-fill complexity doesn’t slow down inspection—containers are verified in real-time, ensuring defective or underfilled products are caught immediately without bottlenecking your line.

3. Foreign Material Detection at the Same Time

While verifying fill levels, Peco InspX X-rays simultaneously check for foreign material contamination like metal, glass, bone, or stone—something a traditional checkweigher can’t do at all. One machine does the job of two, reducing equipment footprint and operational complexity.

4. Detailed Process Feedback

Peco InspX systems generate granular inspection data for every container. You can trace fill inconsistencies back to individual filler heads, optimize upstream operations, and maintain tighter control over your process—all critical for maintaining high quality and high yield in multi-fill production.

A Better Path Forward for Modern Canning Lines

For multi-fill canning operations, relying on conventional checkweighing alone is a recipe for inefficiency. X-ray inspection technology from Peco InspX offers a robust, high-speed solution that improves accuracy, reduces waste, increases OEE, and delivers full-container foreign material detection—all in one compact system.