Speed and precision are the lifeblood of modern glass packaging lines. Whether you’re bottling sauces, spirits, juices, or jams, every second—and every container—matters. But with high speeds come higher risks: glass breakage, foreign material contamination, underfills, and packaging defects can cause costly slowdowns or even full line stoppages.

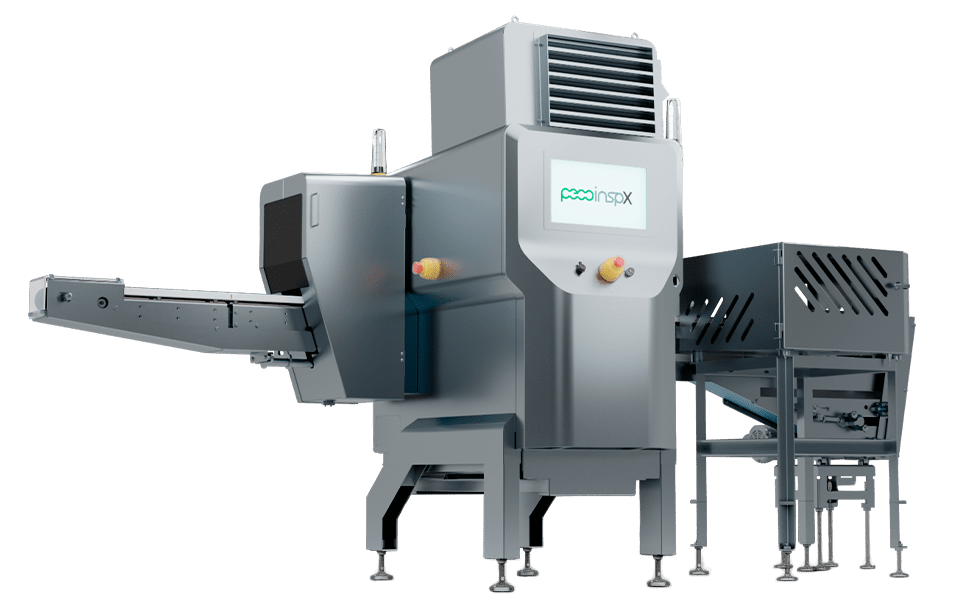

That’s where Peco InspX X-ray inspection systems come in—purpose-built to protect your operation at the highest speeds.

Designed for High-Speed Glass Packaging

Peco InspX systems are proven performers on some of the world’s fastest glass lines, seamlessly inspecting everything from babyfood jars at 1000 cpm (Containers per minute), to glass bottles at 1600+. Our X-rays deliver full-spectrum inspection—keeping up with the pace of your line without missing a single container.

Protecting OEE with Non-Contact, Over-the-Conveyor Solutions

Downtime is the enemy of productivity. Unlike traditional inspection equipment, Peco InspX X-ray systems install directly over existing conveyors—no need to rework your line layout or add complex rejection mechanisms. Because inspection is completely non-contact, your glass containers move smoothly and swiftly through the line, preserving—and often improving—your Overall Equipment Effectiveness (OEE).

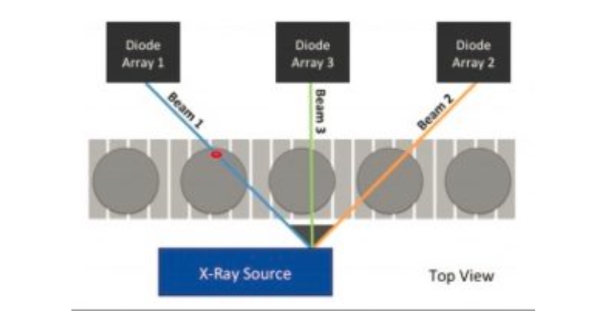

ScanTrac Trio X-ray: Detecting Glass-in-Glass and More—Before It’s a Problem

Glass packaging comes with unique challenges, the most serious of which is the risk of glass-in-glass contamination. Peco InspX X-ray systems are highly sensitive to foreign material inside glass containers, especially in the punt area, which is the most difficult to inspect.

The ScanTrac Trio is designed with three X-ray beams aligned at different angles which provides full inspection coverage of the container. This is especially important around the punt where glass shards are most likely to fall and become hidden from traditional X-rays.

This three beam system is effective at the highest speeds, like beverage bottlers at 1800cpm. With this comprehensive view, the Trio can also detect:

- Chips, cracks, and other container defects

- Fill level deviations, including under and over fills

- Missing or misapplied closures

By removing defective or contaminated containers early, Peco InspX helps prevent blockages, damage to downstream equipment, and product recalls—saving you time and protecting your brand reputation.

Pinpoint Accuracy for Process Improvement

Beyond inspection, our X-ray systems generate detailed data for every container. On high-speed lines, this allows you to trace issues back to specific filler heads or capping stations, enabling fast corrective action, continuous process improvement and informed preventive maintenance.

Meeting Rising Retail and Regulatory Standards

Major retailers and regulatory bodies are raising the bar for product safety and integrity—especially for glass-packaged goods. Peco InspX gives you the confidence to meet and exceed these demands, while maximizing throughput and minimizing cost.